At Medifit, we believe that the exemplary products start with strong concepts which are not just a theory or model, but a “guiding principle”. Our concepts take birth at the problems our users face and go through the rigorous process of solution hypotheses, deliberation and risk assessment. Every aspect of the concept gets documented as the “Reference Principles Document”.

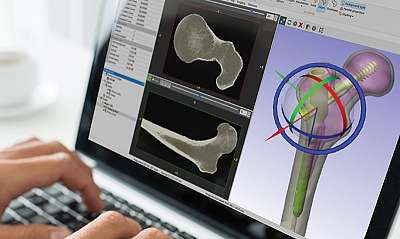

From New product idea or Concept generation Concept Development, we move to arrive at a “Sensible Design” by evaluating the feasibility of the chosen concepts while considering all major project risks, including manufacturing obstacles and regulatory strategies. We achieve this by fully defining the design inputs (drawings, models & specifications), evaluating risks, and identifying and testing critical design features.

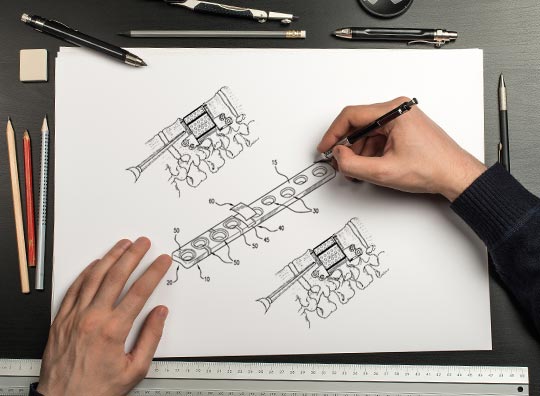

Our teams of surgeons, engineers and machinists use an iterative development process to ensure delivery of a broad range of clinically relevant implant solutions to the operating room with a pace and quality that is unmatched in the industry. Central to our efforts are committed engineer-machinist teams that incorporate clinical insights from surgeons during development, testing, evaluation and manufacturing of our products. The superlative creativity of Medifits’ engineers & technicians coupled with the wealth of experience & expertise provides unparalleled insights in our brainstorming and hands-on prototyping sessions. This enables us in rapidly developing the very best and simplest solutions through hand sketches, 3-D, CAD models and prototypes.

Our Product Development teams leverage a rapid design-prototype-test cycle to identify and correct potential issues early during the development of a product. We conduct design verification and validation by testing defined requirements including functionality, strength, wear and fatigue that ensures risks are mitigated at lowest possible. Creating multiple rounds of prototypes and rigorously testing them in cadaver and various testing labs allows us to quickly transform concepts into validated designs. This ability to quickly place ever-improving designs into surgeons’ hands helps result in a quality product at market introduction.

K.O.L. engagement is key factor for success or failure of any new product launch. It is indeed a cornerstone for us. At, Medifit we have specialist management team who ensures continuous engagement with K.O.L. to make sure our product work as intended by using it in simulated conditions. Bi-Directional dialogue actually guide us to achieve our commercial objectives to be realised in proactive manner.

16+ years of engineering expertise of our manufacturing partner help transition of prototype to successfully run in manufacturing set up.